New product developments for poultry processing equipment

JF Equipment, one of South Africa’s leading developers of poultry processing machinery, has begun developing equipment previously only available by import.

The first of these machines, which will be available later in 2008, is an inside outside washer designed to reduce the cost of ownership for abattoirs the world over.

“Developing products that are cost effective, of the best quality and incorporate the best technology available on the market is our goal at JF Equipment,†says Pat Young, Sales Director for JF Equipment.

The evisceration process involves six complex stages, each requiring highly sophisticated equipment which is complicated to repair and use parts that are both expensive and time-consuming to obtain. In order to reduce these costs of ownership for abattoir operators, JF Equipment is developing a line of evisceration equipment that will incorporate the best principles of equipment design commensurate with achieving low cost ownership. This new equipment will be designed, manufactured and installed using local expertise.

Stages of evisceration process

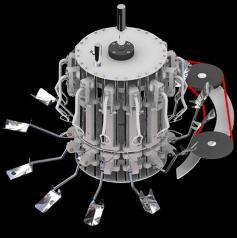

The six stages of the evisceration process start with the Vent Cutter, which prepares the chicken for the next operation by removing the complete cloacal sphincter without breaking the intestine. Following this, the Opening Machine makes an incision from the popes nose to the keel bone, in preparation for the spoon on the Eviscerator to enter the abdominal cavity and remove the contents. Once the edible offal has been harvested, the birds enter the Cropper, where the crop, trachea and neck glands are removed. The neck breaker then does exactly that, and the birds finally enter the Inside/outside wash machine.

Why the new design?

The aim of the new design of these six machines will be to improve ease of maintenance, make parts cheaper and allow for complete cleaning. To this end, the cam drums normally found in these machines have been replaced by hollow tracks supporting segmented synthetic cam units.

“It is our goal to offer abattoir owners a line of poultry processing equipment that is efficient and cost effective,†says Young. “By developing products based on proven and efficient principles will not only make our products better value for money but will allow for an increased yield on behalf of the abattoirâ€.

JF Equipment will be taking orders for the new evisceration equipment from August 2008.

Related link:

Beheer

Beheer

WP Admin

WP Admin  Bewerk bericht

Bewerk bericht