Monitoring key aspects allows proper process control

Chicken processing is a permanent effort to minimise losses and achieve the highest possible quality. By monitoring and controlling specific aspects, quality, safety and yield of the processed chickens can be significantly improved.

By Eduardo Cervantes Lopez, Barranquilla, Colombia

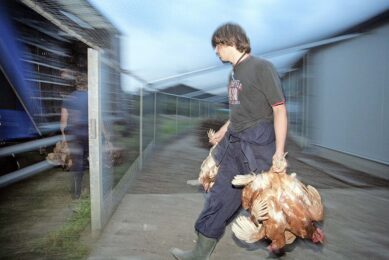

On arrival at the processing facilities, the chickens are hung on the shackles and moved to the stunner. The breast should then remain in permanent contact with the breast comforter. This has a relaxing effect on the birds, which facilitates a proper stunning. If the entrance to the electric stunner is different than the scalder’s entrance, the chickens move up over a ramp where the wings are the first point of contact with the equipment surface.

If this contact area is wet, then it is electrically charged, so chickens will receive a pre-shock, which will cause them to instinctively lift their neck and wings. Some birds remain in this position during their 12-second transit through the stunner, thus staying conscious. Should this happen, they must be unloaded from the shackles, although this is difficult.

The chickens not properly stunned bleed in the tunnel in a painful manner. In other occasions, the bleeding time is not enough, so the birds enter the scalder alive and therefore drown.

Faecal matter before evisceration

When the bird is fed on time, every four hours, faeces are evacuated from the caecum to the colon normally. If, for any reason, the bird fasts excessively, faecal matter starts to accumulate in the caecum, because the evacuation to the colon is delayed. When the chickens are not properly stunned, they struggle in the shackles during the bleeding stage. This struggle of the bird hanging from the shackle produces muscular contractions, which puts significant pressure on the digestive system.

When the bird is fed on time, every four hours, faeces are evacuated from the caecum to the colon normally. If, for any reason, the bird fasts excessively, faecal matter starts to accumulate in the caecum, because the evacuation to the colon is delayed. When the chickens are not properly stunned, they struggle in the shackles during the bleeding stage. This struggle of the bird hanging from the shackle produces muscular contractions, which puts significant pressure on the digestive system.

Since the caecum is full of faeces, its contents is forced into the large intestine and is finally released through the vent, as a stool that falls on the bleeding tunnel floor. This situation is not evident during scalding, mainly because the water washes out the faeces. If scalding and plucking equipment is not properly set and calibrated, the plucking machines will exert overpressure on the birds, compressing the digestive system further, thus causing the same undesired effects. As in the scalding stage, in this case the water used during the plucking and in the outside washer cleans the chickens.

Finally, if the transfer of the chickens from the conveyor to the evisceration line is not automatic, the birds arrive to a special collection table after they pass by the hock cutter. If the ergonomic conditions are inappropriate, they will accumulate on the table and their own body weight will put further pressure on the intestines, forcing the faeces out of the vent. This causes a contamination problem before the evisceration.

Proper bleeding

Blood represents approximately 7% of the total live weight of a chicken. In an industrial operation, bleeding is about 45%, therefore, the birds should have already lost around 3% of their total live weight prior to entering the scalder. Frequent monitoring of this weight difference is very important: if the weight loss increases by 1%, this represents a yield loss of 2.000 kilos (624 tonnes) per year, in a process running at 100.000 birds per day, with an average live weight of 2 kg per bird.

Blood represents approximately 7% of the total live weight of a chicken. In an industrial operation, bleeding is about 45%, therefore, the birds should have already lost around 3% of their total live weight prior to entering the scalder. Frequent monitoring of this weight difference is very important: if the weight loss increases by 1%, this represents a yield loss of 2.000 kilos (624 tonnes) per year, in a process running at 100.000 birds per day, with an average live weight of 2 kg per bird.

In those countries where the neck and head are sold together, if the cut in the neck is too deep, the head is likely to be removed and lost during the de-feathering operation. When birds are not properly slaughtered, that is, the trachea and cervical nerves are cut off, they die in the bleeding tunnel by either asphyxia or heart failure, since the vital organs will not receive control messages from the brain. These substandard situations translate into major losses, because valuable carcasses and giblets must be discarded. In a normal process, no more than 0.03% of the daily processed birds should present bleeding problems.

Four variables

During the scalding operation, four variables must constantly be monitored: time, water temperature, water agitation and immersion. The two latter are directly responsible for follicle opening and feather release. When these variables are not under control, birds tend to float: they move sideways through the scalder, which causes the feathers of the tail and the wings to rise above the water. These two types of feathers are the most strongly attached, so the pickers need to be closed more in order to compensate for the additional effort. In many plants, unfortunately, the way strongly attached feathers are dealt with is by increasing the scalder water temperature. This decision has the following negative consequences on quality and yield:

· Breast over-scalding appears as a series of white stripes on the surface of the breast muscle. These stripes contain proteins denatured by the excessive heat.

· Areas of the skin with low feather cover will be most impacted, because they are not well protected against the extreme temperatures.

· Subcutaneous fat melts away and reduces the yield by about 0.5% to 2.0%.

· Over-scalding causes a shortening of the muscle fibers and irreversibly stiffens the meat.

Gizzards becomes stained

Under normal conditions, about 30% of the chickens suffer an extended feed withdrawal, since they normally need to eat every four hours. After a 12-hour fasting, due the action of reverse peristalsis, the gizzard becomes stained with the greenish colour of bile. This problem is usually detected in more than 40% of the gizzards arriving at the processing station.

Under normal conditions, about 30% of the chickens suffer an extended feed withdrawal, since they normally need to eat every four hours. After a 12-hour fasting, due the action of reverse peristalsis, the gizzard becomes stained with the greenish colour of bile. This problem is usually detected in more than 40% of the gizzards arriving at the processing station.

As a consequence of this prolonged fasting, the chicken loses weight and becomes dehydrated. The gizzard cuticle adheres firmly to the muscle and now its removal requires a longer time on the peeler rollers. This additional processing represents significant losses of gizzard meat, reaching sometimes 80% of the gizzard yield.

Proper use of water

Once the carcasses have totally been eviscerated, they should be washed inside and outside, in order to remove any foreign objects. Moreover, it is necessary to completely drain the abdominal cavity to reduce the organic load of the pre-chiller. The new inside-outside washer (IOBW), drains water automatically. If this apparently small step is not monitored, the water of the pre-chiller and chiller will rapidly turn red. In consequence, the quality control supervisor will need to order more frequent changeovers of the water of both tanks, thus increasing the operational costs of the plant.

Once the carcasses have totally been eviscerated, they should be washed inside and outside, in order to remove any foreign objects. Moreover, it is necessary to completely drain the abdominal cavity to reduce the organic load of the pre-chiller. The new inside-outside washer (IOBW), drains water automatically. If this apparently small step is not monitored, the water of the pre-chiller and chiller will rapidly turn red. In consequence, the quality control supervisor will need to order more frequent changeovers of the water of both tanks, thus increasing the operational costs of the plant.

During the chilling stage, water agitation and the movement of submerged carcasses ensures that the required level of water uptake is achieved. On the other hand, transit time and water temperature, determine the temperature of the carcasses as they exit the chiller. The water temperature should be close to but below 1ºC. On average, breast temperature should be 2ºC higher than the water temperature. In case of over-scalding, the molten skin fat becomes visible as foam in the chiller water, causing an additional yield loss between 0.5% and 2.0%.

Rapid packaging

The key aspect for success in this operation is the speed of bagging and clipping of the carcasses and giblets. After they leave the chillers, carcasses start losing the water taken up during the previous stage. This increases the shrinkage, and affects the yield of the processed chickens.

The key aspect for success in this operation is the speed of bagging and clipping of the carcasses and giblets. After they leave the chillers, carcasses start losing the water taken up during the previous stage. This increases the shrinkage, and affects the yield of the processed chickens.

MORE INFORMATION |

Join 31,000+ subscribers

Subscribe to our newsletter to stay updated about all the need-to-know content in the poultry sector, three times a week. Beheer

Beheer

WP Admin

WP Admin  Bewerk bericht

Bewerk bericht