Implementing a quality and traceability system in Russia

Poultry production in Russia is undergoing rapid changes. Increased awareness of consumers and other third parties require a reliable quality and tracking and tracing system to be in place. The poultry sector as such, with its integrated structure, is perfectly suited to automate such a system.

By L.P. Bessonova, L.V. Antipova and S.V. Polyanskich, Voronezh State University, Russia

Poultry meat and poultry products, eggs and egg products have a high nutritional and biological value. Production and consumption in the world is steadily growing, since poultry is the first type of animal protein that comes to maturity in a developing market. Production of poultry products in the Russian market is currently characterised by a sharp rise due to the use of modern, western technology. Figure 1 clearly shows that the greatest rise of the Russian poultry industry began in the late 1940s and lasted until the end of 1988 and from then (with the fall of Berlin wall, opening up of Eastern Europe) went into a sharp recession. As a consequence, the market was quickly filled with products from Western global and multinational manufacturers.

The famous American chicken legs literally filled the domestic market in the 1990s, which led to the departure of many former Soviet poultry giants. Some survived with financial aid from the government or private investors and were able to turn themselves into multinational manufacturers that successfully implement their products abroad.

The rapid growth of the domestic industry began in 2001 and continues to this day. The growth of domestic poultry production can be attributed to several factors:

• Import quotas for poultry, introduced in the second quarter of 2003.

• Increased profitability of the industry due to increased prices for chicken – the result of the quota.

• Short production cycle, which attracted a large-scale influx of investors to the poultry industry.

• The national project “Development of Agriculture” which provided subsidies on the interest rate for loans for construction and reconstruction of poultry complexes. In addition regional budgets were available on top of that.

Safety concerns

The beneficial properties of poultry meat and poultry products to the human body can only be realised if they are safe for consumption, i.e. they do not contain foreign inclusions – chemical toxins and other harmful substances, as well as pathogenic microorganisms that cause food poisoning. Over the past three years the European Union sharply increased attention to the problems of bacterial contamination of poultry products, including poultry carcasses infected by Salmonella, Listeria and Campylobacter bacteria. In particular, studies conducted in the United States and Poland, confirmed the presence in poultry of Campylobacter jejuni resistant to some antibiotics.

Also E. coli resistant to some antibiotics were revealed. For this reason, in the developed countries the use of most antibiotics – used as growth promoters in feed for farm animals including birds is prohibited.

Safety solutions must be sought in the establishment of a traceability system which will control the entire path of the product in the processing chain. Such a system has to have complete documentation for a product’s manufacturing process and contain options for going back into the production chain to identify resources used, which all need to be found in case of an adverse event. The system as a whole is to ensure food safety for consumers, by:

• Reducing risk in the manufacture of products, the possibility of rapid reaction on an extraordinary situation;

• Identification of all potentially dangerous products, simplify the review and withdrawal at any stage of their life cycle;

• More rapid backward tracing – in a stepwise movement from the product to the source – of potentially hazardous substances that have led to negative consequences;

• Strengthen controls on identified high risk areas to prevent similar problems in the future;

• Minimise financial losses during the recall of products as it is possible to review only certain batches of the product;

• Reduce consumers’ negative reactions to the incident.

Integrated production

The poultry industry in Russia, relative to other livestock sectors in the country, has several features that facilitate the introduction of a system of traceability in the production of poultry products. Unlike most foreign productions, on which the breeding and growing of birds are concentrated on a set of small farms, and the slaughter of poultry is carried out in large enterprises, raising, slaughtering and production of poultry products in our country is mainly concentrated in single enterprises. Broiler farms have increased their capacity significantly in recent years.

Approximately half of the volume of the required poultry feed is manufactured on site. Poultry farms in accordance with the animal health rules are enterprises of “closed type”. The whole process of growing and processing of poultry is carried out by experts under one leadership and control.

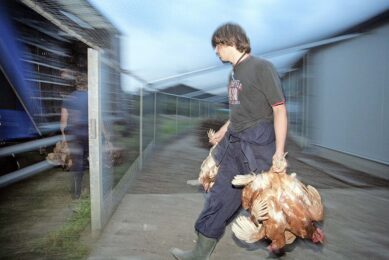

Particular attention in the production of live birds is given to feed safety and cleanliness in all stages of production. Sanitary – hygienic condition of transport means for transportation of live birds, hatching eggs and eggs for sale is also an important feature in food safety.

Risk factors for salmonella infections can be:

• Inadequate safety system of a poultry processing plant, including unreliable cleaning and disinfection between shifts;

• Poor hygiene control during transportation and broilers to the slaughter plant;

• Spreading of faeces from poultry houses, and

• Cross-contamination of carcasses – during slaughter and further processing of raw products.

Visually, the factors affecting the safety of poultry meat products, are shown in Figure 2. The common factors for all stages of poultry production include:

• Adherence to veterinary and sanitary requirements;

• Sanitisation of equipment, facilities, transportation equipment;

• The human factor;

• Personal hygiene of workers;

• Rodents, insects, etc.

Critical control factors at different stages of production are:

• hatching eggs;

• feeding;

• the use of antibiotics and chemicals;

• genetically modified feeds (GMF);

• climate in poultry houses;

• foreign matters, etc.;

• processing of a sick birds.

Stepwise setup

The first step in creating a documentary based traceability system should be a review of existing procedures and operations in the manufacture of the product. To do this, in the first phase the sequence of operations should be determined, beginning from the purchase or acceptance of raw materials and ending with the realisation of the final product. Operations in accordance with the scheme should be carried out parallel to documentation of information about the product. The internal traceability system will be different for poultry farms, depending on the structure of its member enterprises. For instance whether it has parent stock, a feed plant, hatchery, slaughter plant, further processing of products, etc.

Then the technological scheme of processing bird carcasses can be represented schematically. For a simplified presentation of information in the database computer, we introduce some abbreviations (Table 1). The technological cycle of production of poultry meat is a coherent sequence of structural elements. If it is structured in such a way that all information can be put into a computer database it is possible to automatically control all factors affecting the quality of the ready-made product and the entire production process. This reduces the number of staff, increases the organisation of employees, improves product quality, and reduces costs.

Join 31,000+ subscribers

Subscribe to our newsletter to stay updated about all the need-to-know content in the poultry sector, three times a week. Beheer

Beheer

WP Admin

WP Admin  Bewerk bericht

Bewerk bericht