US Study: Campylobacter in poultry processing workers

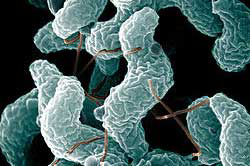

A study published by the Center for Disease Control and Prevention’s Emerging Infectious Diseases journal into Campylobacter infections among poultry processing workers found 29 cases of lab-diagnosed Campylobacter infections during a three year period from January 2008 to May 2011

The study took place in a poultry plant in Virginia, USA, that processed 300,000–350,000 birds per day. The plant employed around 1,000 of which approximately 24–35 were residents of 1 of 2 local diversion centers (i.e., participants of a 16- to 20-week residential work assignment program operated by the Virginia Department of Corrections).

There were two main processing areas. The first processing – birds were unloaded, shackled (in an area called live hang), stunned, killed, scalded, defeathered, eviscerated, and chilled and second processing. The second processing – carcasses were rehung, washed, cooled, and packaged.

The study found that of the 29 people who were diagnosed with Campylobacter infections, 23 were infected with C. jejune, 1 with C. coli, and 5 with an unspecified Campylobacter species. And most of the cases occurred among employees in the live-hang area.

It was also revealed that 83% of those infected had worked at the plant less than a month before becoming ill. And almost all of the sickened employees lived in state operated diversion centers.

It may be that long-term workers develop immunity to the bacteria. But the number of Campylobacter infections may be much higher than the study indicates, since the facility does not have paid sick leave, and workers don’t have easy access to medical care. Employees may be reluctant to report illness or call in sick because they lose wages.

The study’s authors recommended that plant management strengthen efforts to reduce Campylobacter contamination, particularly in the live-hang area. Efforts should incorporate engineering controls, such as improved sanitation, ventilation system modifications, and installation of hands-free soap dispensers and waste receptacles. Plus improve employee training, (in Spanish and English), to teach compliance with hand hygiene and personal protective equipment, especially amoung temporary staff. And these facilities should keep good records of employee illness and make sure that all cases and outbreaks of bacterial infections are reported to health departments.

Join 31,000+ subscribers

Subscribe to our newsletter to stay updated about all the need-to-know content in the poultry sector, three times a week. Beheer

Beheer

WP Admin

WP Admin  Bewerk bericht

Bewerk bericht