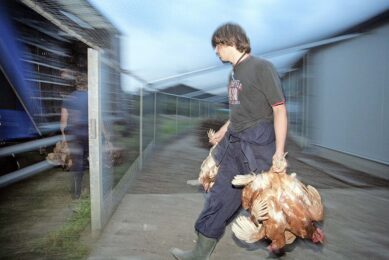

Keep the processing plant clean

Food contamination easily occurs at the origin, read the processing plant. Inhibitory preservatives may extend the products’ shelf life but the doses used and potential residues left, are also harmful to human health. Changing packaging is an option. The best solution however, is to avoid biofilm formation through adequate cleaning.

By Ad Bal

Salmonella spp. are widespread foodborne pathogens that contaminate poultry meats. Attachment, colonisation, as well as biofilm formation capacity of Salmonella spp. on food and contact surfaces of food may cause continuous contamination. Formation of biofilm may play a crucial role in the survival of salmonellae under unfavourable environmental conditions, such as in poultry processing plants. This could serve as a reservoir compromising food safety and human health. The addition of antimicrobial preservatives extends shelf lives of food products, but even when products are supplemented with adequate amounts of preservatives, it is not always possible to inhibit the microorganisms in a biofilm community.

Different patterns

To further investigate the functionality of these preservatives, a study was conducted in Turkey. The aims were to determine the minimum inhibitory concentrations and minimum biofilm inhibitory concentrations of selected preservatives against planktonic and biofilm forms of Salmonella spp., isolated from chicken samples and Salmonella Typhimurium SL1344. Also to show the differences in the susceptibility patterns of the same strains versus the planktonic and biofilm forms to the same preservative agent. And finally to determine and compare antimicrobial and anti-biofilm effects of selected food preservatives against Salmonella spp.

Preservative agents

For this purpose, Salmonella Typhimurium SL1344 and four Salmonella spp. strains isolated from chicken samples were used. As preservative agents, pure ciprofloxacin, sodium nitrite, potassium sorbate, sodium benzoate, methyl paraben, and propyl paraben were selected. As a result, it was determined that minimum biofilm inhibitory concentration values are greater than the minimum inhibitory concentration values of the preservatives. This result verified that familiar resistance seen for antimicrobial agents and disinfectants is also necessary for preservatives in a biofilm community.

New strategies

Regarding the resistance of a bacterial biofilm to antimicrobial agents, new strategies should be implemented for the control of biofilm. In conclusion, increasing the amount of preservatives is not recommended due to the harmful doses in humans. Designing new compounds or inhibiting biofilm formation by changing the packaging properties of food seems to be a more appropriate option. And avoiding the formation of biofilm by keeping the hygienic conditions in the processing plant at the highest possible level of course.

Source: Buket Er and co-workers, Ankara, Turkey, Poultry Science, 2014, Vol. 93

Hygiene at Chirina in Georgia

In 2013, the largest fully integrated poultry producer in Georgia became operational: Chirina Ltd. With an annual production of 12,000 tonnes of meat, Chirina is the leading supplier of chicken on the Georgian market. Hygiene takes the highest priority in each process at Chirina. For that reason, flooring specialist Bolidt supplied Bolidtop 700. This thermosetting synthetic flooring has no pores and is laid in a seamless application, which prevents the growth of bacteria. Its high scratch resistance ensures that this protection is maintained. The floor finish is characterised by high resistance to impact and wear. As the system is impermeable to liquids, it also prevents harmful substances from penetrating into the substrate. As a result, Chirina complies with HACCP requirements and germs are kept at bay.

[World Poultry magazine Vol 30 nr 5, 2014]

Join 31,000+ subscribers

Subscribe to our newsletter to stay updated about all the need-to-know content in the poultry sector, three times a week. Beheer

Beheer

WP Admin

WP Admin  Bewerk bericht

Bewerk bericht