Scheduling feeds for female parent stock in production

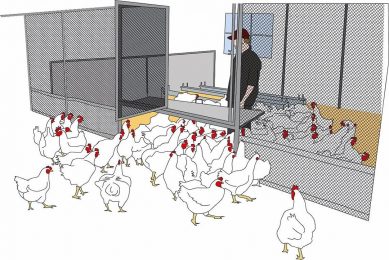

In general, growers choose 1 of 2 accepted methods to feed broiler breeders during the production period.

- The first is to distribute feed in the dark: A few minutes before the lights come on in the morning, or up to 1 hour after the lights come on but also then using dark-out feed distribution.

- The second option is to feed the flocks 7-8 hours after the lights come on: This programme is called late-morning feeding. The lights are switched off in dark-out production facilities during feed distribution, and then switched back on when the first loop with feed has come around. This option is preferred when there are issues with feed distribution, eggshell quality, labour, or too high floor and slat eggs. Proper environmental control with efficient tunnel ventilation and evaporative pad cooling is essential to avoid heat stress related issues.

Getting the right lighting programme

The recommendations below for the second feeding option are best for mechanical community nest systems with wide egg collection belts. Always try out new concepts in one house and have controls to be able to compare. Lighting programmes are key to successful feeding during production. Consider the information below based on your specific housing type:

- Dark-out houses: There is increased flexibility when all lights are artificial to customise when to start the light program and how many hours of total light the flock receives without external light influences. Example, flock starts at 24 weeks of age with an average of 3 % production with 15 hours of total light. If lights come on at 3 a.m., start feeding the birds at 11 am (+8 hours). The lights should be turned off at 6 p.m. Houses must be light proof. This can be done in many temperate climates around the world and in locations above 30-35º latitude north or south.

- Open-sided/transparent curtained houses: Use maximum natural light duration to determine the appropriate light program. Example, with 14 hours of total natural light duration give to the flocks 15 hours to have a fixed total light duration that is higher than the total natural light. Lights come on at 4:30 am and feeding is done at 11:30 a.m. (+7 hrs) and lights go out at 7:30 pm. For flocks with less than 14 hours total natural light, the light programme starts when it is still dark outside and lights are switch off in the dark in early evening.

There are clear advantages to late-morning feeding, including the fact that most of the egg production of the day has already occurred, see Table 1. Over time, as flocks get older, some egg production will shift gradually to the afternoon.

With mechanical nests there should be two 25cm wide central belts with a divider in the middle on which the hatching eggs can accumulate for 6 to 7 hours without negative consequences for breakage or hairline cracks. This concept is used in large operations with egg packers. When eggs are collected on the egg table at the end of the house normally 3 to 4 hours of eggs are accumulated on the egg belt system. With manual nests egg collection needs to start maximum 3 hours after the light programme starts.

Early-afternoon feeding

Some companies delay feeding even more and go to early-afternoon feeding. Most of the metabolic heat production of the birds happens then in late afternoon when temperatures are lower.

Understanding the concept:

- Imprint the programme at 12 weeks of age, gradually delaying the moment of feeding towards 11 a.m. and completing the transition by 16 weeks of age.

- If using daily feeding in rearing, the programme can start as of 5 weeks with the feeding hour fixed at 11 a.m.

- Feeding in rearing 1 to 2 hours after the light programme starts also leads to less-nervous flocks. Birds maintain a good distribution over the whole house. Their fine internal clock advises when feeding time is coming up.

- Houses are black-out during rearing; the lights switched off for feed distribution. It is very important the house is close to pitch black. The darkness helps keep birds calm and will give a much better feed and bird distribution over the whole feeder system. After all the feed has been distributed the lights are switched on again and the birds position themselves quietly at the feeder track.

- During the production period in dark-out houses, the same dark-out feeding concept is used reducing bird agitation and egg peritonitis. In open-sided or transparent curtain houses, some pen structure till peak production needs to be used for proper bird distribution over the whole house so that all nest openings are used proportionally.

- Once the flock is moved to the production house, the birds are accustomed to this late morning feeding programme and there will be following advantages:

- After 7 hours in young PS flock, more than 88% of the daily production has been produced in the nests. No hens will be pulled from the nests due to early morning feeding, which reduces floor eggs by 50%.

- In the first 20 to 30 minutes with the lights on, males mate actively, there is more male-female interaction.

- Because the intestinal tract is empty during lay, the eggs are potentially cleaner with less contamination.

- Eggshell quality is improved. The calcium in the feed in late-morning feedings goes straight to eggshell formation.

- Farm personnel need not to be present at early morning feeding. This eliminates overtime hours and easier to attract and retain personnel with regular daytime hours.

- Any feeding equipment issues are more easily repaired at 11 a.m.

To conclude, there are essentially 2 ways to schedule feeding in the production period. Each company will need to determine what works best under local conditions and evaluate the benefits of both programmes.

Author: Ing Winfridus Bakker

Join 31,000+ subscribers

Subscribe to our newsletter to stay updated about all the need-to-know content in the poultry sector, three times a week. Beheer

Beheer

WP Admin

WP Admin  Bewerk bericht

Bewerk bericht