Sustaining broiler feed intake at high stocking densities

At the stocking densities currently used commercially, it’s usually necessary for broilers to have to actively compete at feeders once bodyweight reaches a certain minimum physical size.

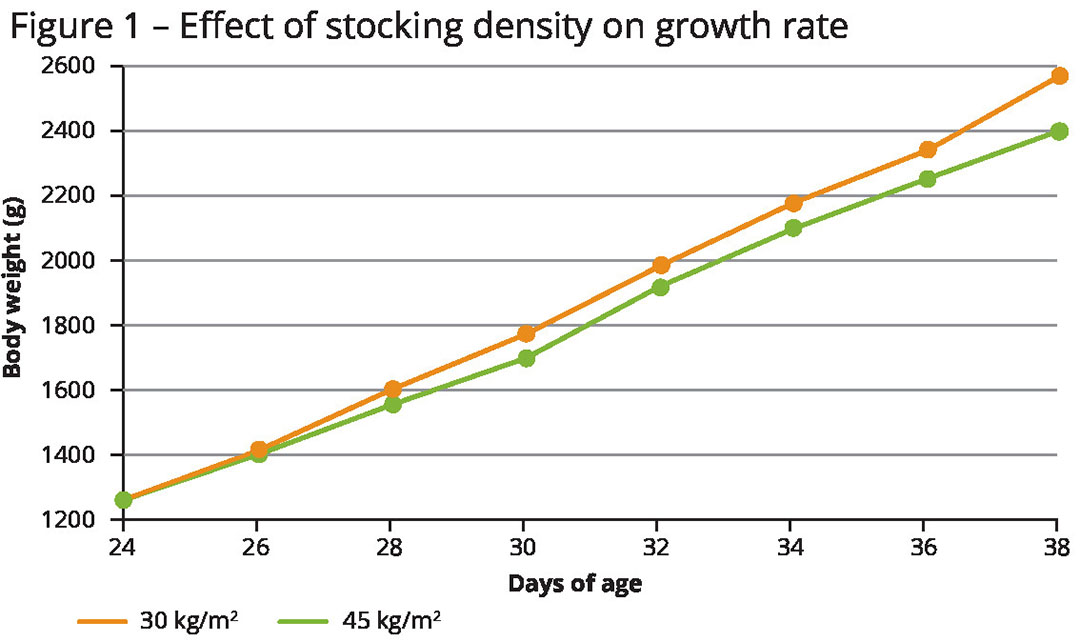

This physical crowding at the feeders first becomes noticeable at around 28 days (d) of age, when birds reach about 1,650 grammes. Consequently, it’s often seen that broilers meet the standard weight of around 1 kg at 21d, but from 28d onwards birds invariably lag behind their genetic potential. Figure 1 shows the growth rate of broilers close to genetic potential using 30 kg/m2 stocking density compared to reduced growth at 45 kg/m2, with this effect related to differential feed intake.

Over the range of 25-50 kg/m2 stocking density, each +1 kg/m2 increases feed intake of the 2.5 kg broiler by 30 g, essentially due to prolonged grow-out time. We invariably blame this reduced growth rate on some aspect of the ‘finisher’ diet or some generalised stress or subclinical microbial challenge. In many instances the effect is simply reduced feed intake caused by limited access to feeders.

Over the range of 25-50 kg/m2 stocking density, each +1 kg/m2 increases feed intake of the 2.5 kg broiler by 30 g, essentially due to prolonged grow-out time. We invariably blame this reduced growth rate on some aspect of the ‘finisher’ diet or some generalised stress or subclinical microbial challenge. In many instances the effect is simply reduced feed intake caused by limited access to feeders.There has been a trend towards increased stocking densities over the past 20 years or so, especially in situations where ventilation systems have been upgraded. Once a broiler house has been constructed, it’s very rare for the number or location of feeder and drinker lines to be changed. Consequently, the main impact of increased stocking density on broiler growth has been unintentional feed restriction. Associated prolonged grow-out to market weight also reduces feed efficiency. Sustaining feed intake – or rather nutrient intake – at higher stocking densities therefore becomes critical to optimising production efficiency.

Calculations show that broilers need to eat for about 8 minutes every hour, yet this is never achieved in a single session. In fact, the majority of feedings last for less than 20 seconds. Obviously, the shorter the duration of individual feedings, the greater the number of times the bird must approach the feeder.

To some extent, the greater the number of birds at the feeder the greater the positive impact of so called ‘social facilitation’ meaning that birds are more attracted to feeders actively being used by their flock mates, although this is a minor effect compared to the the issue of limited feeder space. Options for sustaining nutrient intake at high stocking densities include consideration of diet nutrient density, pellet quality and lighting programmes.

Diet nutrient density

It would seem to be a simple solution just to increase nutrient density as stocking density increases, to normalise nutrient intake. However, adjusting energy to theoretically compensate for reduced intake is often an issue regarding cost, especially given current prices of cereals and fat.

Table 1 highlights calculated specifications designed to equalize nutrient intake for broilers grown at 30 vs 45 kg/m2. Both energy and amino acid levels are extreme at 45 kg/m2 and thus rarely acceptable to integrators and certainly an issue for feed retailers. The energy level in this diet can only be achieved with a significant inclusion of fat which, apart from current cost, is an issue for maintaining pellet quality.

Pellet quality

It’s usually accepted that feed intake is maximised using pellets rather than mash diets, and so pellet quality becomes a very practical issue for broilers grown in high stocking densities. In the finisher period when the broiler is eating around 200 g feed/d, birds will consume around +5 g/d of a diet at 80% vs 60% pellets, even at moderate stocking densities. At higher densities this may be an underestimate of the impact of pelleting on feed intake.

Some recent data suggests that pelleting per se improves the digestibility of the feed, although the classically suggested effect of ‘starch gelatinisation’ is probably much less than anticipated and does not come close to accounting for the overall benefit of pelleting.

Almost 50 years ago, Leo Jensen showed that the main advantage of pelleting was reduced energy used in all aspects of feeding activity. In effect, pelleting improves the net energy (NE) of the diet, rather than AME, but of course we accommodate for this effect within AME energy requirement values and corresponding diet specifications. For example, it is generally accepted that under moderate stocking density, it is possible to achieve standard broiler growth and feed efficiency with mash diets, simply by increasing diet energy level. Obviously, there are limits to this approach as stocking density increases.

As shown in Table 1, a practical limitation on increasing nutrient density at high stocking densities is the price of energy. Unlike the option of using synthetic amino acids to accommodate increased diet inclusions, we have no real substitute for diet energy expressed as AME. However, we can influence energy need by reducing maintenance needs for sustaining body temperature and by improving pellet quality. Maintaining broilers at <15°C is going to be challenging at high stocking densities, so keeping broilers as close to a thermal neutral of around 24°C is going to minimise energy needs at a high (or low) stocking density.

Increasing pellet quality is another option for effectively increasing the energy level of the diet, accomplished through the hidden effect of reduced maintenance NE needs. Table 2 shows calculated energy (NE) equivalents of changing pellet quality. Improving pellet quality from 60-80% effectively increases diet energy by 60 kcal/kg by directing energy from maintenance to production. Improving pellet quality is therefore an important goal when feeding broilers at higher stocking densities.

Since one major advantage of pelleting is that it allows birds to eat faster and so occupy proportionally less feeder pan space, then feeding as large a pellet as possible will obviously optimise this concept. In general terms, nutritionists are cautious about increasing pellet size according to age based on the assumption that birds cannot handle a larger diameter or length of pellet, especially when younger.

Largest pellets

When given a discrete selection of feed in mixed particle sizes, birds invariably show a preference for the largest particles. This situation becomes obvious when ‘fines’ accumulate in the feeder pans over time. As pellet size increases so the bird needs to consume fewer pellets and so spend less time at the feeder.

Table 3 shows the effect of pellet size on the number of pellets the bird needs to consume. Strictly from a bird preference point of view, and in terms of maximising feed intake, Table 4 provides an overview of optimal pellet size for starter through finisher diets. Naturally, this idealised pellet size must be balanced against the willingness of mill managers to accommodate the necessary changes in pellet die size. Matching pellet size to bird age becomes critical as stocking density increases.

Lighting programmes

Broilers are reluctant to eat in the dark and so lighting programmes have an impact on both total feed intake and on occupancy rates at feeders. Birds will maximise their intake with continuous lighting, although a period of darkness is either mandated or used to prevent leg disorders and improve general immune response.

Step-down, step-up programmes are common in controlled-environment houses where a maximum of 6-8 hours of darkness is often used. A significant number of broilers are grown globally in open-sided houses and seasonally the dark period will be 10-12 hours a day. Providing 20 h light vs 16 h light per day results in around 200 g more feed for a 2.5 kg bird, so faster growth. Broilers rarely eat significant quantities of feed in the dark period unless this is extended much beyond 1 continuous period of 6 hours.

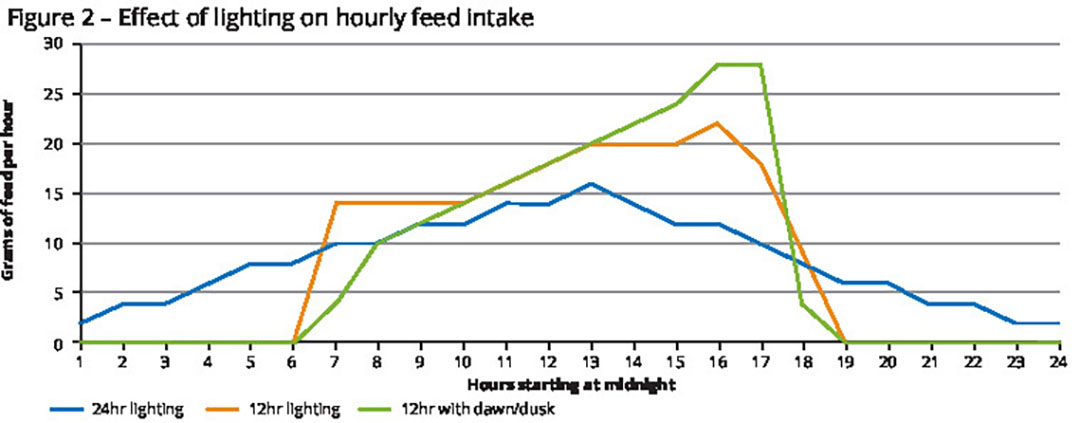

Beyond 6 hours of darkness, birds consume about +1% of their feed in the dark period per additional hour of darkness. With 12 h darkness then almost 6% of daily intake can occur in the dark period, often resulting in skin tearing and cellulitis. This situation is undoubtedly more acute at higher stocking densities. Apart from impacting total feed intake, the lighting programme further impacts feeder occupancy rates and hourly consumption (Figure 2).

Beyond 6 hours of darkness, birds consume about +1% of their feed in the dark period per additional hour of darkness. With 12 h darkness then almost 6% of daily intake can occur in the dark period, often resulting in skin tearing and cellulitis. This situation is undoubtedly more acute at higher stocking densities. Apart from impacting total feed intake, the lighting programme further impacts feeder occupancy rates and hourly consumption (Figure 2).

With continuous lighting there is a subdued ahemeral pattern to feed intake, peaking around midday, likely because of birds cueing to non-light stimuli, such as noise or temperature change, etc. With a 12 h period of light feeding activity is necessarily more concentrated and, interestingly, birds show maximum feeding activity in the few hours preceding ‘lights out’.

Imposing a dawn/dusk programme on the schedule that involves a gradual increase in intensity at ‘lights on’ and a decrease in intensity prior to the dark period, causes a major shift in feeding activity, being highly skewed to the hours of dusk (Figure 2). Presumably the birds’ cue more acutely to the reducing light intensity and increase feeding prior to lights out.

Such intense feeding activity at the end of the day is going to be an issue with high stocking density, since feed pan numbers, etc., are usually calculated on the basis of more continuous hourly feeding. Table 5 shows calculations of feeder space adequacy as affected by simple changes to hours of darkness, without the added detriment of dawn/dusk lighting.

In this simulation, there are 60,000 broilers in a house equipped with 1,000 feeder pans. At the end of cycle 10, 2.5 kg birds can feed at a pan at any one time. With 23 hours of light per day, the maximum occupancy rate of 9,000 birds can be accommodated. With only 14 hours light, then feeder pan space during maximum feeding activity suggests a 50% inadequacy of pan space.

Within limits

In conclusion, sustained nutrient intake is the key to success when using increased stocking density. There are economic limits to solving this issue simply by increasing diet nutrient density. At high density it is essential to optimise pellet quality, while from a management perspective, hours of light every day should be maximised within the limits of sustaining bird health and welfare.

Increasing stocking density invariably worsens the performance of individual flocks but it usually increases farm profitability over a given period. This article provides insight into how to optimise both parameters.

Join 31,000+ subscribers

Subscribe to our newsletter to stay updated about all the need-to-know content in the poultry sector, three times a week. Beheer

Beheer

WP Admin

WP Admin  Bewerk bericht

Bewerk bericht