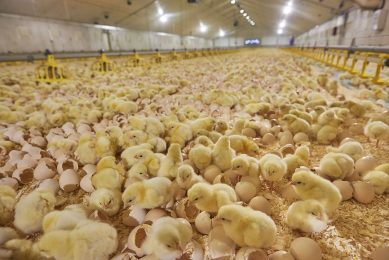

HatchTech launches technology to maximise hatchability and chick quality

HatchTech, producer of Incubation Technology, has launched a new feature on its MicroClimer Setters that maximises hatchability and chick quality: The Uniform Embryo Activator.

One of the first and most important steps in the incubation process is the warming of eggs from storage temperature to the optimal incubation temperature. With the Uniform Embryo Activator, the complete warming process takes place inside the incubator itself. The Uniform Embryo Activator gradually increases air temperature in incremental steps from the storage temperature to the ideal incubation temperature over a carefully fine-tuned time frame.

Improved hatchability

When the embryo temperature increases at the start of incubation, embryo development is activated. With the Uniform Embryo Activator, embryos are gradually warmed using a unique time and temperature profile that ensures optimal embryo development. HatchTech states that with this special profile, chicks develop optimally and hatchability is maximised.

Increased uniformity

The MicroClimer laminar airflow technology is a crucial factor in the success of HatchTech’s Uniform Embryo Activator. Laminar airflow ensures uniform embryo temperatures in the egg mass. All embryo’s are activated in the same way. Uniformity of early embryo activation means that hatch time, chick development and chick quality, are all uniform .

“This new technology is a result of intensive research and close cooperation between our research and development departments,” said Joost ter Heerdt, Sales Director HatchTech. “Our research (Reijrink et. al, 2010) demonstrated the importance of the benefits of a special temperature profile to warm the eggs from storage to incubation temperature. We are proud that we have developed a special tool which helps our customers to maximise their hatchery results.”

The Uniform Embryo Activator offers more benefits. Since UEA, gradually increases the air temperature, no condensation on the eggs occur, which prevents bacterial contamination. What’s more, with UEA, there is no separate warming process in the corridor between the setters, which saves unnecessary handling. And since UEA can be programmed for a delay start, all of this results in more labor efficiency .

Source: HatchTech

Join 31,000+ subscribers

Subscribe to our newsletter to stay updated about all the need-to-know content in the poultry sector, three times a week. Beheer

Beheer

WP Admin

WP Admin  Bewerk bericht

Bewerk bericht