A comprehensive poultry biosecurity programme as a prerequisite

If there is one lesson learned from the pandemic, it is that the global supply chain is vulnerable to disruption. The poultry supply chain is not invulnerable. Just as Covid-19 disrupted, avian influenza can disrupt the supply chain because flocks of chickens that test positive for the disease are eliminated.

Achieving food security in poultry production requires the involvement of many areas of the production continuum and success depends on continuous management. Production managers must be able to lead their team members and have a solid knowledge of all the connections in the continuum to produce an environment that facilitates poultry health and food security.

As a broiler breeder producer, we are at the beginning of the food production chain. Keeping our breeders healthy and secure serves as a strong foundation for food throughout the entire production chain. We accomplish this security by implementing a detailed and rigid biosecurity programme. Biosecurity must be the focus of a breeder management programme. Broiler breeders are on the farm for a significant amount of time and are responsible for generating eggs for the broiler industry.

Clearly, biosecurity must be integrated with farm management practices, protocols and standards developed to reduce the risk of introducing disease into the flocks. The development of a strong biosecurity programme involves many factors, including employee commitment and training that stresses the importance of strict enforcement.

Development

The breeder production process must begin with day-old chicks free of pathogens. Once on the farm all biosecurity measures must be employed to maintain this pathogen-free status. However, it is impossible to control all the processes related to rearing and production without having rigorous guidelines as part of good management practices (GMPs). These practices are not generic, and each programme must map its operations related to rearing and fertile egg production and handling.

The first step is to identify and describe all the important farm activities. The second step is to define which activities represent a potential risk of pathogens entering the operation. Finally, this risk assessment exercise can be used to define the best steps to take to avoid pathogen risks. For example, avian influenza is typically transferred horizontally. Initial exposure is typically oral, but as infection increases (3 to 5 day incubation) in the flock, conjunctival and respiratory routes of infection are possible. Normal waterfowl can carry avian influenza in their gastrointestinal tract.

With that knowledge, taking action to limit direct contact with potentially contaminated wild birds is critical to a sound biosecurity programme. Taking action to protect flocks from sources of avian influenza includes monitoring feed and water supplies. Develop policies that prevent team member exposure to waterfowl and equipment or clothing that may have been contaminated by wild bird faeces. This would include exposure to birds through hunting, backyard flocks, and zoos.

Cobb team members that come into contact (intentionally or accidentally) with birds outside must report the exposure to their supervisor and follow the corporate minimum farm withdrawal time (72 h) before returning to the poultry farm. This time may be extended to 7 days if a team member is exposed to diseased birds.

Flocks do not become infected with disease by chance. By going back over the processes, with all the standards, controls and records available, we can trace the source of an infection. Traceability is as important as providing the clues necessary to determine the potential source of infection to prevent any future flock infections. Ask appropriate questions, listen to the answers, use that information to find the security breach and make recommendations to restore flock biosecurity. Consider the following biosecurity basics.

Farm location

Before the first chicken house is built, consider the proximity of other poultry farms and place as much distance between farms as possible. The topography and drainage of the units must prevent water pooling around the houses and inside them. Vegetation can act as a barrier but could also provide unintended refuge for wild birds and animals.

Keep poultry houses at a safe distance from busy highways or roads, especially roads that are regularly used by poultry vehicles. Site selection also includes avoiding farm ponds, lakes and streams that bring waterfowl close to your farm.

Sanitary gate

A physical barrier, such as a sanitary gate, must reflect the importance of the work conducted on the property. At the gate, facilities are required to undertake adequate cleaning and sanitizing, using wet or dry methods, of all essential vehicles accessing the property.

Other physical barriers, including gates and fences, must be checked daily. Holes in fences or opened gates cannot be tolerated. Wash bay arches should be monitored to ensure proper pressure and operation. Wash bays must also use appropriate disinfectants at the active dosage.

People, vehicles and materials

The procedures required to enter the facility must be clear to all personnel. Only after disinfection and registration can they access the facility. Procedures for material disinfection must also be clear. Company team members who work at locations other than the farm and non-team members (visitors and contractors) may be granted access to the breeder unit after being evaluated and authorised by the team member responsible for the barrier. They must undergo an assessment including the person’s origin, previous contact with birds, health condition and purpose of visit. If all the pre-requisites are not met, entry must be refused.

Vehicle access should be severely restricted. Access should be given only to vehicles designated as essential, including feed, eggs, placement, poultry transfers and processing vehicles. For non-essential vehicles, a questionnaire must be completed that includes the vehicle origin, while cleaning and disinfection must be performed. In addition, collect information that enables the adequate traceability of all vehicles entering the farm.

Food and water quality

Cost of raw materials is important, but quality and security are more important and must be based on good production practices in producers’ feed mills. The feed milling, transport and silo filling on farms must follow clear procedures to maintain the feed microbiological quality. Water should meet high physico-chemical and microbiological standards. To sustain water quality, it should be chlorinated and regularly monitored, sampled and analysed.

House access

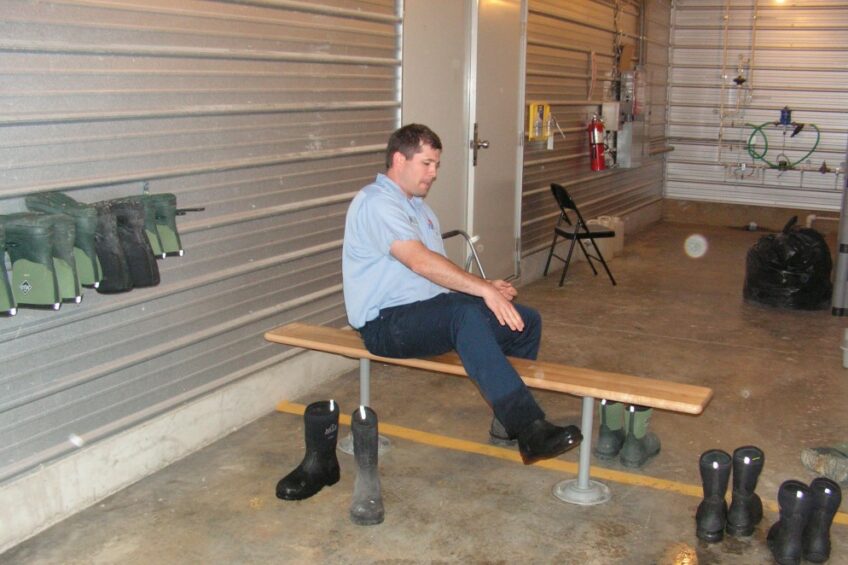

Access to poultry houses should have the same control and rigor, physical and chemical barriers, as the facility barrier to reduce the risk of flock infection. Boot cleaning using footbaths with liquid or powder products, washing, and hand sanitization with alcohol gel are good practices included a biosecurity programme. Keep poultry houses closed to prevent wild birds from entering the house.

A preventive programme for rodents and flies must be in place and maintained according to a schedule and checklist. If these controls are not performed as scheduled, the risk of pathogen entry increases. Check local regulations regarding the products used to control rodents and insects, as they must be approved for use in the facility. Furthermore, ensure that insecticides and rodenticides are checked and stored properly.

Good practices inside

The daily operations within the houses are also critical to flock health and safety. Some key points include:

Spilled feed will attract wild birds and rodents. After filling feed bins, immediately clean and remove spilled feed and ensure feed bin covers are kept closed.

Eggs must be collected at least 4 times a day (up to 6 during peak production) and placed in storage in a temperature-controlled environment. Delay can compromise egg integrity, creating an environment that facilitates contamination.

Wash and sanitize hands for all tasks, including egg collection, sorting and weighing, as well as flock weighing, vaccination and grading.

Maintain floor sanitation as wet floors provide a good environment for micro-organisms to multiply.

Applying good animal welfare principles that ensure flock comfort, meeting feed and water standards, controlling the environment and handling flocks carefully, will promote a high level of flock health.

Cleaning and disinfection

Create a standard cleaning and disinfection protocol and check observance of the protocol through monitoring and auditing activities. This programme should be validated with microbiological methods. Modify and adjust detergents and disinfectants based on the results of the validations and audits. No disinfection should take place before thorough cleaning is complete.

Washing the structures well and using effective detergents are required to reduce organic material that can harbour pathogens. Follow thorough disinfection with regulatory approved agents that are effective against specific micro-organisms.

Check and double-check

The guidelines discussed in this article should be included when designing a biosecurity programme. A good overall validation of your biosecurity programme will include checking medication use, the incidence of disease, mortality and health programme costs, as these factors can indicate weaknesses in the biosecurity programme.

Additionally, training team members with constant monitoring and audits, also form part of an effective biosecurity programme that targets biosecurity, poultry health and welfare. Biosecurity must be a part of the farm’s standard operating procedures and not something that becomes important only when disease is found on your farm or close to it.

Join 31,000+ subscribers

Subscribe to our newsletter to stay updated about all the need-to-know content in the poultry sector, three times a week. Beheer

Beheer

WP Admin

WP Admin  Bewerk bericht

Bewerk bericht