Enzyme supplementation optimises poultry feed potential

Many companies are seeking ways to reduce costs in feed and livestock production. As a result, the use of exogenous enzymes is becoming more prevalent to improve nutrient digestibility and lessen the financial impact of rising costs and poor feed efficiency.

The agriculture industry has accomplished some amazing feats in the last 60 years, proving how adept the industry is at change and innovation. However, the steady rise in feed ingredient costs is an obstacle for many producers today. Disease, farm mandates, climate change, geopolitical tensions and supply chain challenges continue to affect feed ingredient prices and several analysts predict high prices are here to stay well into 2023.

Feed enzyme production methods

When feedstuffs become scarce or price sensitive we must consider advanced solutions to maintain a proper diet to meet the genetic potential of the animal. Using feed enzymes is one of the most promising innovations in agriculture. Feed enzymes not only help improve digestibility and decrease the environmental impact of agriculture, they also enable producers to save money.

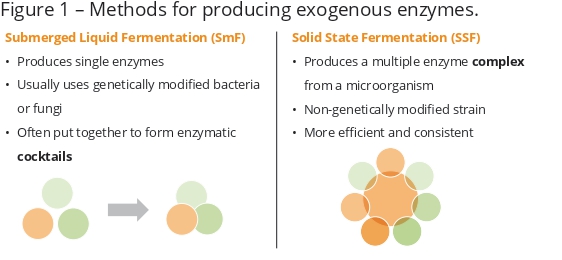

A wide range of enzymes are available on the market, differing in production method, activity and use case (Figure 1). Enzymes are complex molecules produced commercially through microbial fermentation. Most feed enzymes are produced by means of submerged liquid fermentation (SmF) or solid-state fermentation (SSF) processes using microbe strains selected or genetically modified to produce a single, specific enzyme.

A wide range of enzymes are available on the market, differing in production method, activity and use case (Figure 1). Enzymes are complex molecules produced commercially through microbial fermentation. Most feed enzymes are produced by means of submerged liquid fermentation (SmF) or solid-state fermentation (SSF) processes using microbe strains selected or genetically modified to produce a single, specific enzyme.The multiple substrates included in poultry diets result in a mix of anti-nutritional factors and inaccessible nutrients, so it is critical to use a product with multiple enzyme activity. Liquid fermentation enzymes are often mixed to create an enzyme ‘cocktail’ to achieve this, but the use of multiple single enzymes can lead to feed inefficiencies. The enzymes can compete for substrate and inhibit or inactivate each other, compromising their effectiveness in feed.

Using multi-enzyme complexes

Solid-state fermentation, however, produces enzymes in a single complex so they are more able to work in synergy with the animal’s digestive tract, allowing the enzyme solutions to enhance digestibility and nutrient use across a wide range of feed materials (Figure 1). This allows the producer to use less expensive alternative raw materials and less of them because more nutrients are being extracted from the feed. Multi-enzyme complexes such as Alltech’s Allzyme technologies help fibre and protein to become more digestible, meaning producers can take advantage of this when formulating diets by feeding lower-cost feed ingredients, using locally sourced grains and thus saving money on the diet.

Continuing enzyme innovation

Over the past 3 years, Alltech’s research in enzyme technology has been directed towards product development with a focus on greater nutrient release. Allzyme Spectrum is the next-generation multi-enzyme complex that maximises nutrient utilisation by breaking down substrates typically found in a poultry diet, such as non-starch polysaccharides (NSPs) and phytic acid.

The enzyme has proven its efficacy in laboratory research, university trials and commercial settings. This extensive work has shown that the new enzyme can save at least 90 calories per kilogramme of feed in poultry diets. This efficiency gain provides flexibility in reformulation through the use of alternative raw materials, helping producers to save money. Broiler and layer research trials conducted at the University of Kentucky, USA, and presented at the International Poultry Scientific Forum and Poultry Science Association, have demonstrated the benefits of including the enzyme in nutrient-reduced diets. Allyzme Spectrum enhances nutrient utilisation and supports a healthy digestive system.

Broiler research

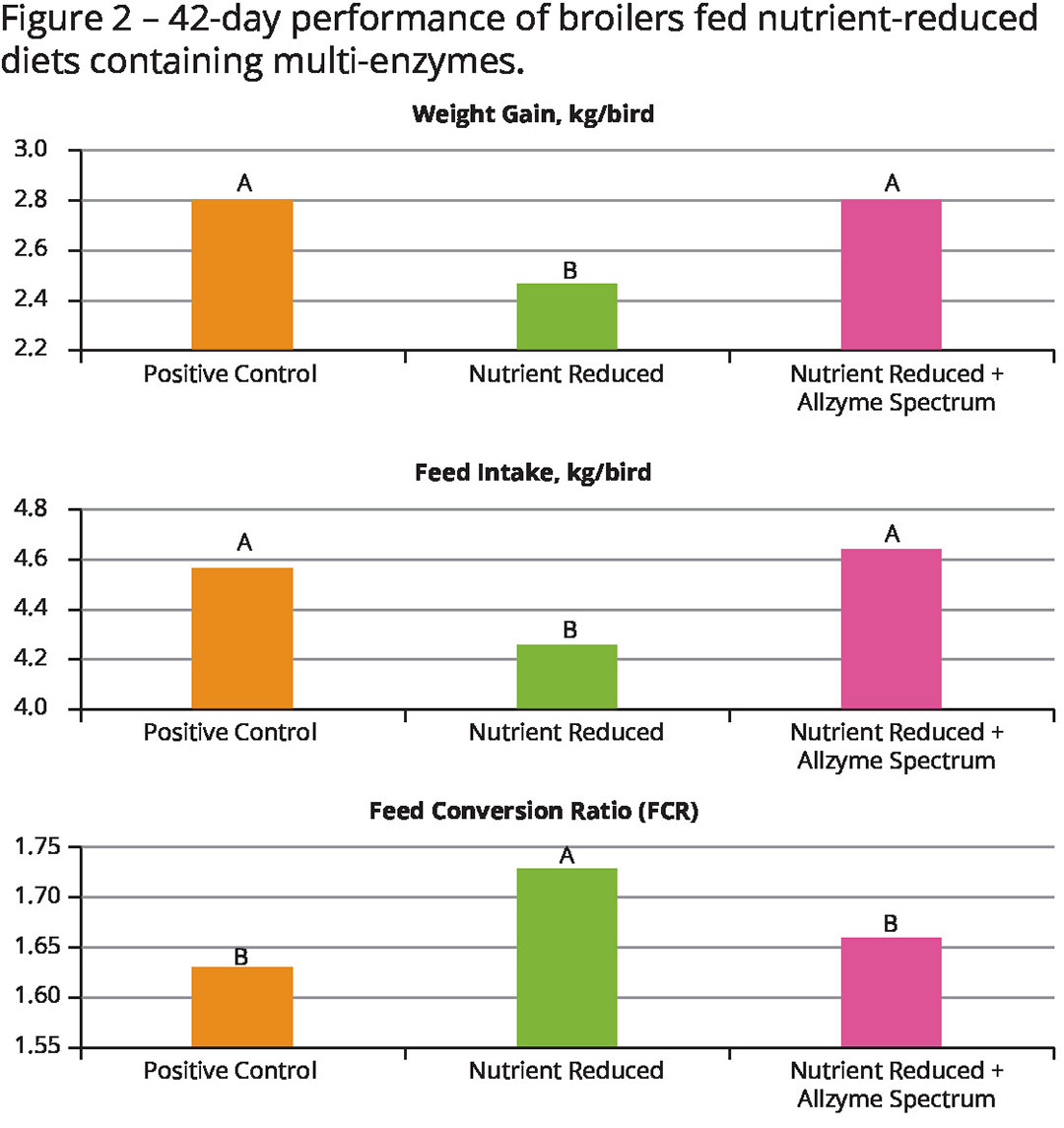

The 42-day performance of commercial broiler chicks was evaluated after feeding the following corn-soybean meal-based diets:

The 42-day performance of commercial broiler chicks was evaluated after feeding the following corn-soybean meal-based diets:

- Positive control (commercial level energy and nutrients)

- Nutrient reduced (-90 kcal/kg ME, -0.15% available phosphorus (aP), -0.15% calcium (Ca.) vs. diet 1)

- Diet 2 + 200 grammes per tonne Allzyme Spectrum

The main observations were made in trial 2 (Figure 2). Firstly, the broilers fed the nutrient-reduced diet without enzyme supplementation had the smallest weight gain, feed intake and poorest feed conversion (FCR) ratio. The birds fed the nutrient-reduced diet with Allzyme Spectrum showed the same weight gain, feed intake and FCR as positive control birds provided with commercial-level energy and nutrients.

Layer research

The 44-week production performance of brown layers was evaluated after feeding the following corn-soybean meal-based diets:

- Positive control (commercial level energy and nutrients)

- Reduced Ca and aP (vs. diet 1 by 0.15%) + 250 FTU/g commercial phytase

- Reduced Ca and aP (vs. diet 1 by 0.15%) + 200 grammes per tonne Allzyme Spectrum

- Reduced nutrient (vs. diet 1 by 90 kcal/kg ME, 0.15% Ca, 0.15% and aP) + 200 grammes per tonne Allzyme Spectrum

The main takeaways from the layer research were as follows: When enzymes were provided in layer diets there were no differences in feed intake, hen day production or feed conversion, despite reduced nutrient inputs compared to the positive control (Table 1). On top of which layers fed a commercial diet or diets containing reduced levels of nutrients with enzymes did not produce eggs of a different weight, eggshell breaking strength and eggshell percentage (Table 2).

Performance, cost and environment

The inclusion of enzyme products in animal feed is an essential nutritional strategy to tackle key issues in animal production. When the supply and price of conventional feedstuffs, such as corn, wheat and soybean meal, is a challenge, less conventional, lower-cost feedstuffs and waste by-products become more attractive to producers because they do provide some nutritional value. Enzyme supplementation can help birds digest, absorb and utilise energy and nutrients from these less conventional feed ingredients, leading to improved performance with a reduced level of environmental nutrient excretion. Enzymes will be a key component of diets in the future. Innovative nutritional solutions – including multi-enzyme technologies – can help to improve the productivity and profitability of animal production while also providing significant sustainability benefits.

References available on request.

Beheer

Beheer

WP Admin

WP Admin  Bewerk bericht

Bewerk bericht