Evaluating the true impact of feed quality on poultry performance

Animal feed manufacturing poses the challenge of providing the necessary nutrients plus safeguarding the health of the animals that will consume it, as well as the biosecurity of the production facilities and final consumption points.

High-quality feed not only supports efficient growth but also gut health, which in turn promotes general good physiological function. We typically think of feed quality in terms of its formulation, and as a result, nutritionists throughout the industry work towards constantly optimising formulations, but feed quality is also dependent on its physical form and microbial loads. In fact, an increasing number of publications indicates that lowering microbial levels in feed can enhance poultry performance and enhancements in pellet quality lead to decreased fines production and improved feed conversion rates. Additionally, feed can act as a fomite and rapidly and efficiently disseminate pathogens across poultry operations.

Factors impacting feed quality

The balance of the microbial community in the poultry intestinal tract is essential for health and performance. Maintaining a balanced microbiome aids in keeping the gastrointestinal tract in an absorptive state. Imbalances in the microbiome may lead to lesions in the intestinal epithelium, causing a shift from absorptive to defensive mode with a detrimental effect on performance in chickens and turkeys. Elevated levels of microbes in poultry feed can result in health and performance issues by stimulating goblet cells in the gastrointestinal tract to multiply and generate mucus, further generating an environment favourable to pathogenic bacteria. Feed and feed ingredients can harbour pathogens that affect poultry health, productivity, and food safety. These pathogens can multiply in the feed, compete with the host for nutrients and because of the substantial volumes and centralised distribution of feed, it can quickly reach many farms. Studies indicate that various pathogens like Salmonella and Clostridia can thrive in feed mills and equipment, spreading through feed and its ingredients. They act as carriers, reaching trucks, silos, feeder systems, ultimately affecting birds downstream. The systematic and frequent distribution of feed across production chains daily highlights its crucial role as a key control point in biosecurity programmes.

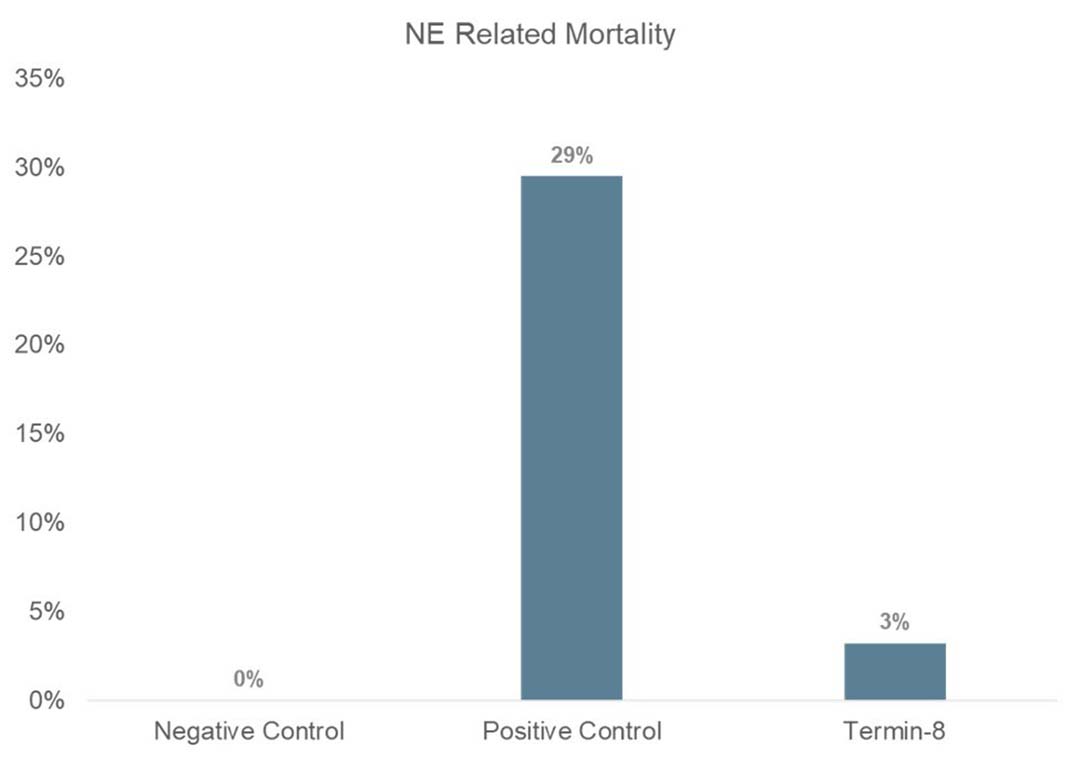

Controlling microbial loads has been linked to improved poultry performance. In recent years, Anitox has worked with Colorado Quality Research to evaluate how reducing feed microbial loads impacts broilers under a Necrotic Enteritis challenge model. Under this model, results have shown that reducing microbial loads in feed positively impacts the development of healthy microflora, lessens the severity of lesions and mortality, supports weight gain and improves feed conversion (Figure 1).

Figure 1- Compared to broilers fed a control diet, broilers fed sanitised feed had lower NE-related mortality as well as mortality and removal (M&R) in a NE challenge model.

Pellet quality

Besides microbial contamination, feed form has an important impact on poultry production. Poor pellet quality results in higher fines production, leading to an uneven distribution of essential nutrients in feed formulations. Commercial broilers and turkeys tend to choose coarser feed particles, with the size influenced mainly by their age. Providing rations with high-quality feed form ensures that the flocks receive nutrients evenly and spend less time searching for feed particles with birds demonstrating better feed intake and efficiency.

For instance, if a broiler diet contains over 40% fines, broiler producers usually experience a 3-6 point decrease in FCR. This results in the need for more feed to reach desired weights and a decrease in broiler feed efficiency.

Studies evaluating feed form impact on turkey performance found that feed with poor physical quality, 50% fines, lead to reduced processing yield, increased FCR, potentially due to more feed wastage, and lower body weights compared to turkeys provided higher quality, sieved rations. This has been tested repeatedly throughout history, with the evidence supporting that feed form impacts poultry performance and birds provided feed with fewer fines require less feed to reach weight targets.

Strategies supporting poultry performance

Implementing feed quality strategies that reduce microbial contamination and enhance pellet quality can assist producers in optimising the value of costly raw materials and maximising their feed investments.

Feed sanitisers like Termin-8 and Finio play a crucial role in reducing feed microbial levels, guarding against re-contamination, and ensuring long-lasting protection. By lowering microbial levels, these sanitisers aid in decreasing pathogen presence in feed, which in turn enhances bird health and performance. This strategy not only promotes food safety and enhances poultry performance but also proves to be cost-effective for producers. Various studies have shown that incorporating a feed sanitiser in both raw materials and finished feed leads to a notable reduction in overall microbial levels and pathogen prevalence. Furthermore, the advantages of feed sanitation can endure for up to 14 days post-application, providing enduring protection.

Pellet quality is critical to broiler and turkey feed efficiency. Feed rations with high pellet quality promote nutrient distribution, enhance flock uniformity and FCR and positively impact poultry performance. By implementing efficient strategies to adjust feed moisture levels, producers can improve the nutritional value and quality of pellets. This optimisation can boost efficiency in feed milling and result in more productive and sustainable broiler and turkey production. Maxi-Mil inclusion during feed production has been shown to improve feed conditioning rates, moisture retention and pellet quality.

Feed quality is critical to poultry performance and influenced by a number of factors. Poultry producers seeking to understand how microbial loads and feed form impact their operation can visit www.anitox.com for more information.

Beheer

Beheer

WP Admin

WP Admin  Bewerk bericht

Bewerk bericht