Replace 14% of broilers’ dietary methionine with crystallised betaine

Can betaine also help to reduce feed costs? Studies carried out recently at the Trouw Nutrition Poultry Research Centre in Spain show that including Selko TNIbetain96 in the poultry diet can replace up to 14% of the broiler chicken’s methionine + cysteine requirements while maintaining broiler performance.

Precision nutrition strategies applied to the broiler chicken diet should consider how nutrients influence bird health and performance, as well as production economics. Betaine offers a good example of an ingredient that can support broilers under a heat stress challenge, and cut farm production costs.

Long used as a nutritional tool to help mediate the effects of heat stress, betaine is known for its positive effect on methylation and its ability to replace other costly methyl group donors, such as choline chloride.

Leveraging matrix value

As a sustained period of high feed prices puts pressure on poultry farms’ financial performance, adding interventions to address the challenges broilers face can raise production costs even more. But there is an opportunity to leverage ingredients in the diet to help manage costs while supporting broilers under a heat stress challenge. That’s where the matrix value of ingredients comes into play.

It’s important to consider how some feed additives interact with other nutrients, potentially creating a nutrient oversupply that goes beyond their main function. Understanding the matrix value of an ingredient in the feed formulation can unlock opportunities to avoid oversupplying expensive ingredients and meet an animal’s nutrient needs with less costly ingredients. Such a strategy may enable formulators to partially replace more expensive ingredients in the diet, such as choline chloride and methionine. It is well known that betaine can replace choline chloride in most poultry diets when matrix values are implemented.

Role of methionine

As one of the most important essential amino acids in protein synthesis, methionine is the first limiting amino acid in broiler diets and its crystalline form (DL-Methionine) is commonly added. Methionine also supplies cysteine and methyl groups. Methyl groups are especially important in mitigating the negative effects of heat stress. Dietary betaine also provides methyl groups, allowing it to potentially replace expensive methionine by serving this specific role.

In vivo matrix value

Understanding that the theoretical replacement of methionine may be significantly overestimated when compared to in vivo results, a trial was conducted to determine the in vivo matrix value of a feed additive (Selko TNIbetain 96) that can be used without suppressing chick performance.

A broiler chicken trial performed at Trouw Nutrition’s Poultry Research Centre showed that 14% of the methionine requirement could be replaced with betaine while still achieving equal performance compared to diets containing the methionine requirement. The trial lasted 35 days and was carried out under thermo-neutral conditions, using corn, wheat and soybean meal-based diets that included 300 ppm choline chloride.

Trials

A total of 6 different treatment groups (Table 1) were established. A control group with betaine added and fully meeting the methionine + cysteine (Met + Cys) requirements. A negative control without betaine but with the same Met+Cys content. Treatments 3-6 also included crystallised betaine at 0.2% but gradually reduced the percentage of Met+Cys provided (lower DL-methionine inclusion).

The birds in the control group (T1) achieved a final bodyweight of 2.618 kg and a bodyweight adjusted feed conversion ratio (FCR) of 1.32 at 35 days of age. This was set as the reference.

The birds in the control group (T1) achieved a final bodyweight of 2.618 kg and a bodyweight adjusted feed conversion ratio (FCR) of 1.32 at 35 days of age. This was set as the reference.

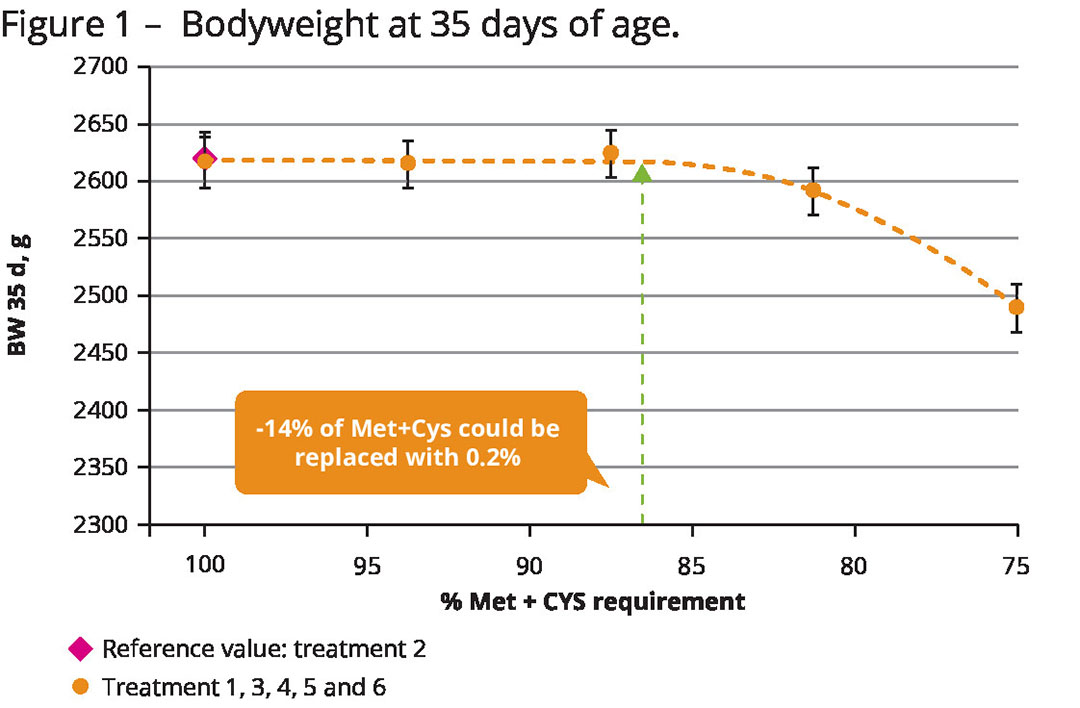

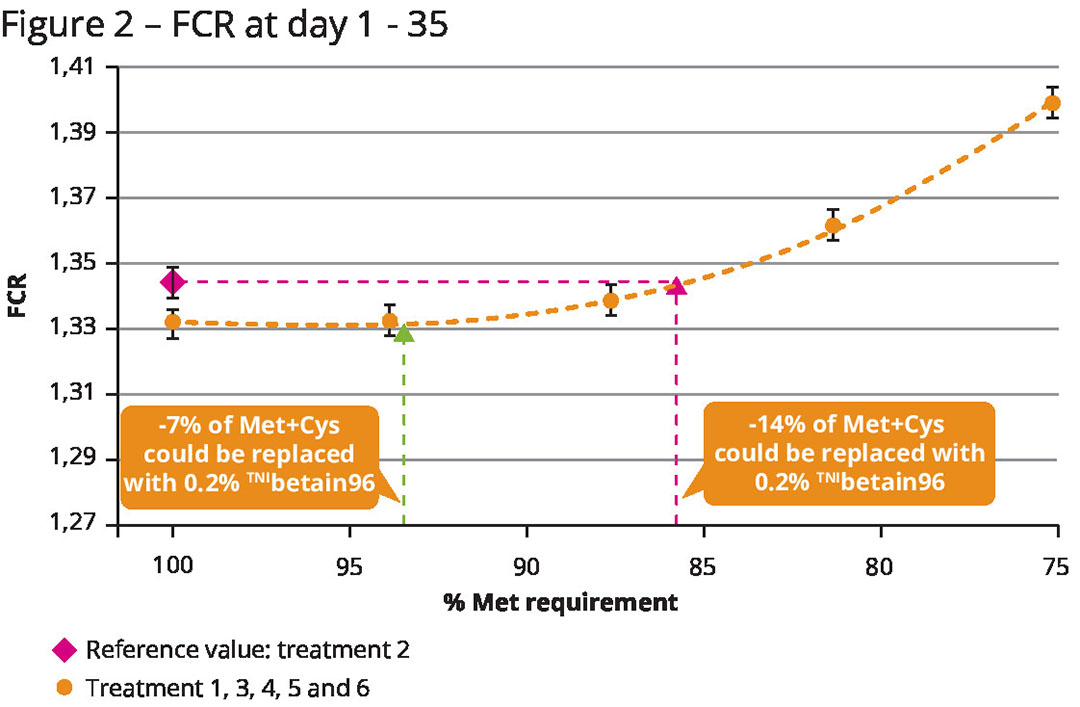

The results in Figure 1 and Figure 2 show the bodyweight at day 35 and FCR over the entire production period per Met+Cys requirement percentage fed. The plateau in Figure 1 is where the reference value is met which means that the birds obtained the same final body weight. The point where the plateau ends is the Met+Cys percentage that achieves the same performance.

Since a significant portion of Met+Cys requirements are met using crystalline Met, adding betaine can partially replace DL-Met. Figure 2 shows a similar possible Met+Cys reduction in the bodyweight data. At the performance level of the control treatment without betaine, a reduction in DL-Methionine by 14% shows a similar performance. Adding crystallised betaine to the diets at 0.2% even offers an opportunity to improve production efficiency by 0.7 points while still dosing 7% less DL-Methionine.

Precision required

Although this trial data clearly shows the capacity of betaine to partially replace DL-Methionine, it is important to understand that using matrix values requires knowledge and experience. The metabolic pathways responsible for the methionine sparing effect of betaine are intricate and it may be affected by other nutrients and factors, such as choline, the methionine supply and the ingredients in the formulation. Thus, the use of correct matrix values is a pre-requisite that can improve precision nutrition and translate into a reduction in feed cost.

Overall success relies on a clear understanding and the robust application of nutrient knowledge. Selko TNIbetain96 has been demonstrated in vivo to support chickens facing heat stress and enhance production economics through the partial replacement of choline chloride and DL-Methionine.

Join 31,000+ subscribers

Subscribe to our newsletter to stay updated about all the need-to-know content in the poultry sector, three times a week. Beheer

Beheer

WP Admin

WP Admin  Bewerk bericht

Bewerk bericht