Preparing the poultry industry for tech disruption

Like hospitals, the poultry industry is about to be radically transformed by robots, the Internet of Things (IoT), and artificial intelligence (AI).

Innovation always brings concerns about job loss – healthcare workers had these fears years ago, and the poultry sector will be no different. But, as the poultry industry embraces IoTs, AI, and robots, poultry farmers have an advantage: by observing the changes in healthcare, poultry farmers can learn and prepare their workforce for the inevitable agtech revolution.

Robots

At the Aalborg University Hospital, robots efficiently transport up to 3,000 blood samples at a stable temperature to ensure accurate analysis and enhanced patient care. And beyond logistical tasks, a robot named PARO responds to touch and sound to reduce stress for patients.

Similarly, robots can assist in the processing plant by managing poultry welfare as well as cutting, deboning, and packaging poultry products. AviSense is an affordable chicken robot that helps poultry farmers make up for labour shortages, increase production index per year, secure animal welfare, and preserve meat quality. The future of poultry includes robots that improve productivity, quality, and safety of poultry operations while reducing labour costs and errors.

Internet of Things (IoT)

By providing real-time and relevant data to healthcare professionals, IoT technologies, such as smart devices and wearables, have transformed the work of hospital staff. These health devices eliminate the need for continuous monitoring, allowing bedside staff to allocate their time to other tasks. IoT can also be used to track doctors, nurses, healthcare workers and even expensive hospital equipment when it moves around.

Several startups and tech leaders within the poultry industry are already working on the use of IoT devices, which can track and optimise the environmental factors, such as temperature, humidity, ventilation, lighting, and air quality, in poultry houses, hatcheries and breeder houses. One example is the Israeli startup YieldX. Using RFID tags and GPS trackers, IoTs can track and manage birds, meat and equipment in the poultry supply chain to improve efficiency, quality, and sustainability while reducing costs and risks.

Artificial Intelligence (AI)

Medical errors, which are estimated to cost the healthcare industry US$1.9 billion annually and result in over 200,000 fatalities, are often caused by doctor or nurse fatigue, memory lapses, misunderstanding, or lack of experience and training. However, AI in healthcare has already improved disease detection and patient outcome predictions.

How can we avoid mistakes on our farms? AI can help us overcome human errors made by farm workers, veterinarians, and nutritionists and accurately analyse data, detecting potential health issues. AI computations can also play a key role in tackling carbon credits and resource scarcity.

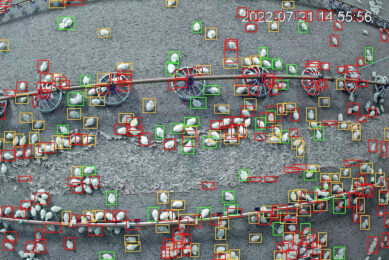

Using camera-vision technology and machine learning algorithms, Birdoo monitors poultry houses 24/7. It helps growers decide on the best time to harvest for optimal nutrition, uniformity and consistency. Unlike the traditional method of weighing birds by hand, using data improves speed and accuracy while lowering labour costs and biosecurity risks. In addition, big data and cloud computing enable farmers to deal with the real challenges they face from weather, genetics, and market fluctuations.

Lessons for the poultry industry

In healthcare, robots, IoT, and AI have both improved healthcare quality and displaced jobs, even highly skilled labour. But we still have medical professionals; their roles have simply shifted to responsibilities that require the human touch. Currently, medical jobs have a 19% job growth and will create more than 2.3 million jobs in the next few years – the most of any industry.

On the other hand, agricultural employment in the US will increase by only 1%. Even before the agritech revolution, agriculture was suffering a “people problem” due to poor pay and harsh conditions.

What does this mean for the poultry industry? Like the transformation we’ve seen in healthcare technology opens the door to more stimulating, higher-paying work that attracts and retains a flexible workforce.

In fact, many argue that AI alone can lead to long-term job growth by increasing productivity and consumption, creating new categories of human jobs that complement the tasks performed by AI systems. Utilising robotics, sensors, and AI to cultivate food with efficiency and precision not only provides secure and economical food sources, but propels poultry workers towards better opportunities and better pay.

Evolving with each innovation

How do we help ensure this outcome? As I noted in my recent book, The Future of Agriculture, education and training programmes are proven ways to cultivate a workforce that evolves with each innovation. A McKinsey survey revealed that more than 50% of large farms and nearly a quarter of small farms are using (or planning to use) precision agriculture technology, so future poultry workers should be recruited with new skills, including data analysis, software engineering, and coding.

At the end of the day, the poultry workers and chicken businesses that will survive the tech transition are the ones investing and embracing high-skill training programmes now. In fact, those who prepare for disrupting innovation will enjoy new levels of productivity, profits, and more job satisfaction.

Beheer

Beheer

WP Admin

WP Admin  Bewerk bericht

Bewerk bericht