Blood rules the quality of the carcass

Like in every living creature, blood is a vital part of the chicken’s body, influencing the most important parts: wings, thighs and breast. Climatic conditions, as well as pre slaughter handling, greatly determines the bird’s blood condition and well-being. And eventually the carcass quality.

By Eduardo Cervantes Lopez, processing consultant, Barranquilla, Colombia

In many parts of the world, cold weather is associated with altitude. When chickens are grown above 1,000 meters above sea level heights, the oxygen content of the air is becoming more scarce.

Recall that in the beach atmospheric, pressure is 760 mm Hg and oxygen is about 21% of all gases that constitute the air. When we climb a mountain, the air pressure is reduced and consequently the availability of oxygen too. Therefore, we feel that temporarily the respiratory rate increases. This is the result of acclimatisation mechanisms of our body to maintain the required volume of oxygen.

That is why the production of red blood cells and therefore the haemoglobin level is increased. This physiological reaction causes the quantity of blood and its increase of respective viscosity.

Veins and vessels

Another aspect that is worth mentioning is that 84% of the blood is contained within blood vessels and 16% in the organs of birds. This 84% is distributed as follows:

- Arteries 15%

- Capillaries 5%

- Veins 64%

Furthermore, both arteries and veins are formed by three layers. As the heart pumps oxygenated blood at high pressure, the arteries are stiffer. The return of non-oxygenic blood goes through the veins that have weaker muscles. This is because the blood is driven by a system of valves which are folds of the inner layer and which prevent blood from flowing backwards.

These structural features have the effect on the blood vessels. Being, the stiffer arteries, the increased volume of blood is not generated in its diameter changes.

In the case of the veins to be the softer formation, they are expanded. This means there is a greater volume of blood circulating within them (see photo below).

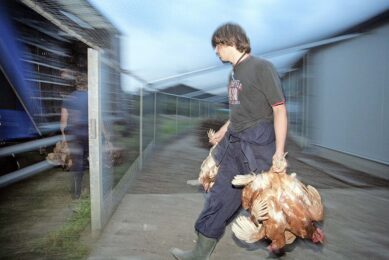

Capture and transport

In the stage of harvesting there are two major operations that affect the integral quality of processed chickens: capture and transport.

The manual capture is usually performed by taking the chicken leg. This allows intense wing flapping when the birds are being put into the cages or containers. When the birds flap, blood flows to the breast and the wings are increased, so that the muscles in these regions have an increased oxygen level. Accordingly, an extra volume of blood in these parts of the body is stored.

Therefore, it is recommended to capture the birds by their body, thus keeping their wings attached to it. As a result, two positive effects are achieved:

- The wings are not mistreated and this will reduce the number of downgradings in the plant.

- When the chickens are placed in cages or containers, most blood will be stored in the thighs. If transportation and waiting at the receiving area are longer, this blood reservoir is a critical factor to keep the birds strong on their legs.

Relaxation needed

In the area of storage and hanging on the overhead conveyor, the following measures should be taken, to prevent flapping of the chickens during handling.

These areas should preferably be darkened and illuminated with blue lights. Some plants also use red or green lights however, prompting chickens to completely relax.

The breast comforter must be appropriate. Once suspended in the shackles, the breast should immediately enter into direct contact with this surface, thus preventing it from flapping, The contact will cause an effect of relaxation.

The time between hanging and stunning must be between 20 and 30 seconds maximum. This short time does not allow a lot of blood to be deposited at the wings due to gravity. Also, if the chickens are not flapping, additional storage of blood in the wings and breasts is avoided. During electrical stunning, the pre-shock causes intense fluttering and chickens stay conscious, because they keep the neck up all the time and don’t reach the stunner.

Ample bleeding time

When chickens are being slaughtered and they have been flapping a lot because of the intense pain they were feeling, increased accumulation of blood will occur in the wings and breasts.

If the bleeding time is very short (about 2.5 minutes), this will be insufficient to release the blood due to vasoconstriction and the large volume of blood that is stored in the wings, legs and breasts. As a result the level of condemnations will be high, due to the poor condition of these parts of the carcass.

When the birds have been killed already, the blood continues to flow out of the carcass due to gravity. If there’s been insufficient bleeding time, and the chickens leave the last plucker, much blood is still released on the way from evisceration to leg cutting. In many occasions, also during the first meters of the overhead conveyor in the evisceration area, often there’s a lot of blood on the floor and the equipment. As a satisfactory solution in many plants, it is recommended to increase the bleeding time up to 3.5 minutes, and in some cases up to 4.0 minutes. By prolonging the presence of chickens in the bleed tunnel, the goal is to release approximately 45% to 50% of the total blood from chickens. Commercially this represents a loss of 3.0% of live body weight, which is the goal. If this parameter is achieved, it will significantly reduce the number of downgrading’s in the processing plant, due to problems of accumulation of blood in various parts of its body.

Avoiding pressure

Complementary to this, is that the entire infrastructure of scalding and plucking should be adequate to avoid exposing the birds to excessive pressure during removal of feathers. This will increase the mistreatment of different parts of the body, especially the wings that is the most fragile region of the chicken.

Source: World Poultry, Volume 30, issue 7, 2014

Join 31,000+ subscribers

Subscribe to our newsletter to stay updated about all the need-to-know content in the poultry sector, three times a week. Beheer

Beheer

WP Admin

WP Admin  Bewerk bericht

Bewerk bericht