Tackling mycotoxins in maize gluten meal

One of the significant challenges the feed industry faces is mycotoxin contamination, in crops such as maize (corn) and its by-product, maize gluten meal (MGM). Recent research by experts at Kansas State University, the University of Foshan and the Mars Global Food Safety Center (GFSC) explores this topic and uncovers potential new ways of risk mitigation.

MYCOTOXIN SPECIAL 2023 – read all articles

Mycotoxins are toxic secondary metabolites produced by certain types of fungi that grow on crops during cultivation, harvest, and storage, and can be enriched during processing, posing additional food safety risks. Maize, and maize gluten meal (MGM), a by-product of maize produced by the wet milling process, is particularly vulnerable to mycotoxin contamination during both pre- and post-harvest phases.

MGM is used to create a high protein, low fat feed for livestock, poultry and domestic pets due to its high levels of digestibility in several animal species including pigs, cats, and chickens. It can also be used as an alternative to meat when supplemented with minerals, adding to its market value for use as an ingredient in animal feed and pet food. In recent years the demand for MGM in food and feed has grown, and as such, a clear strategy to help control mycotoxin risk in MGM is crucial to food safety.

According to MarketsandMarkets (2023) report, in 2022, the global MGM market is estimated at USD 8.4 billion with an annual growth rate of 4.3% from 2022 to 2027. With demand for MGM increasing, enabling the full utilisation of MGM, through the reduction of mycotoxin contamination, will help to meet the global demand for these protein resources and minimise health risks in animals, and to humans who may be exposed through contaminated animal-source food.

Processing of maize into MGM

MGM is prepared by re-centrifugation, filtering and drying of the gluten slurry obtained from the maize starch gluten separation process. Starch and oil-rich germ are the main products from wet milling, comprising of 75% on a dry weight basis. Following removal of these main products, fibre, and soluble components, MGM accounts for about 5% of the dry weight.

Though different mycotoxins exhibit different migration characteristics, published data suggest that most of the mycotoxin types found in maize are concentrated in the gluten fraction during the wet milling process, e.g., 31.3% of aflatoxin B2 found in maize was subsequently distributed into the MGM during processing, followed by ochratoxin A (30.6%), zearalenone (27.7%), trichothecene HT-2 (16.1%). This demonstrates that the tested mycotoxins have enriched significantly through wet milling compared to its 5% of the dry weight of the maize plant. Such enrichment of mycotoxins during wet milling has become a critical challenge for its use in food and feed and underscores the importance of tailored and systematic approaches to mycotoxin control in MGM.

Tackling mycotoxins in MGM holistically

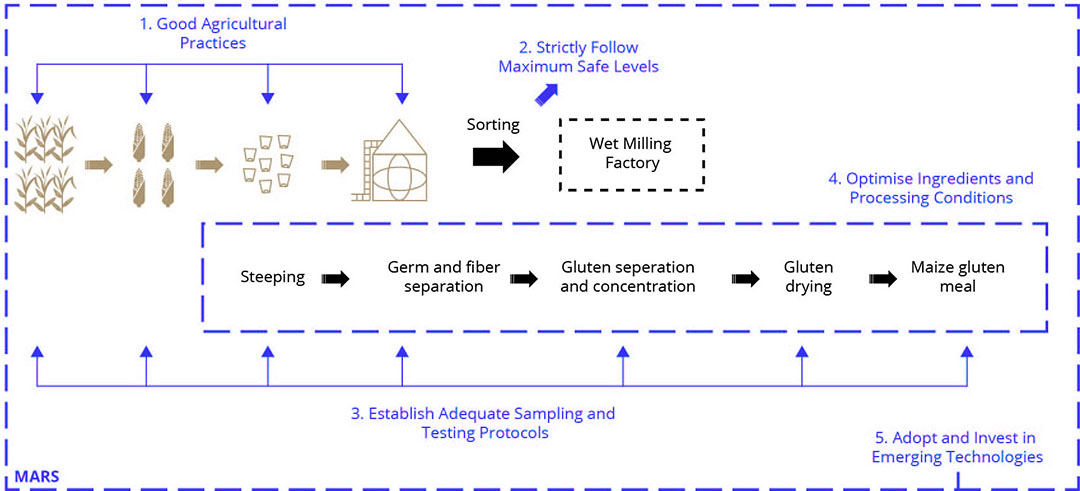

The first key step to take in combating any food safety challenge is to ensure the scale of the issue is well understood for each system. Implementing a systematic control strategy throughout pre-harvest, post-harvest, and processing stages is essential to minimise mycotoxin risks. This approach is best developed by recognising that relying solely on the measured mycotoxin concentration in maize may not accurately predict the concentration in MGM due to mycotoxin enrichment during wet milling. To address this critical issue, our research team has proposed a series of mitigation strategies that can be implemented at various stages of maize production and processing (Figure 1).

Figure 1 – Risk management strategy for mycotoxins in MGM from the field to the end-product.

Ensure Good Agricultural Practices (GAP): Implementing GAP standards is crucial for minimising mycotoxin risks. These practices encompass pre-harvest, harvest, and post-harvest interventions, providing a comprehensive approach to safeguarding crops.

Strictly follow Maximum Safe Levels (MLs): Adhering to MLs guidance is vital to ensure the safety of MGM. These limits vary across countries or regions and help producers and processors take measures to reduce mycotoxin content in maize and its derived products.

Establish adequate sampling and testing protocols: Mycotoxins are not evenly distributed in raw materials, necessitating the development of robust sampling and testing protocols. These protocols should include standardised testing and acceptance sampling to ensure accurate assessment of mycotoxin levels.

Optimise ingredients and processing conditions: The optimisation of processing conditions, such as the use of sulphur dioxide (SO2) and lactic acid bacteria, plays a significant role in reducing mycotoxin risks. SO2 can react with aflatoxin B1 (AFB1) to produce a less toxic compound, mitigating its adverse effects.

Adopt and invest in emerging technologies: Keeping pace with emerging technologies is crucial for advancing food safety. Techniques like sorting methods, cold plasma, and photocatalysis hold great potential in transforming the industry by effectively reducing mycotoxin contamination.

Additionally, collaboration with industry experts and regulatory bodies to develop guidelines that promote the adoption of prevention and mitigation strategies such as Good Agricultural Practices and sampling and testing regimes helps to ensure that mycotoxin contamination can be controlled at every stage of the manufacturing process and can be removed from the value chain as early as possible. By preventing mycotoxin contamination at the source, the reliance on processing techniques to remove mycotoxins is reduced, ultimately safeguarding the food chain.

Building resilience in the MGM supply chain

At Mars, as global food manufacturers, we prioritise food safety and recognise the importance of working together to address mycotoxin risks in maize and its by-products. The collaborative research conducted here highlights the impact of the change in distribution of mycotoxins during MGM production and processing and proposes effective mitigation strategies. By implementing these strategies and fostering collaboration across all supply chain partners, we can protect consumers and animals from the harmful effects of mycotoxins. Together, we can ensure high-quality and safe ingredients in our products, fostering a healthier future for both humans and animals.

References are available on request.

Dr Yueju Zhao took the stage during the World Mycotoxin Forum 2023 held 9-11 October in Antwerp, Belgium. Her presentation ‘The Food Safety Coalition project to address the challenges of aflatoxin contamination in raw materials’.

Beheer

Beheer

WP Admin

WP Admin  Bewerk bericht

Bewerk bericht